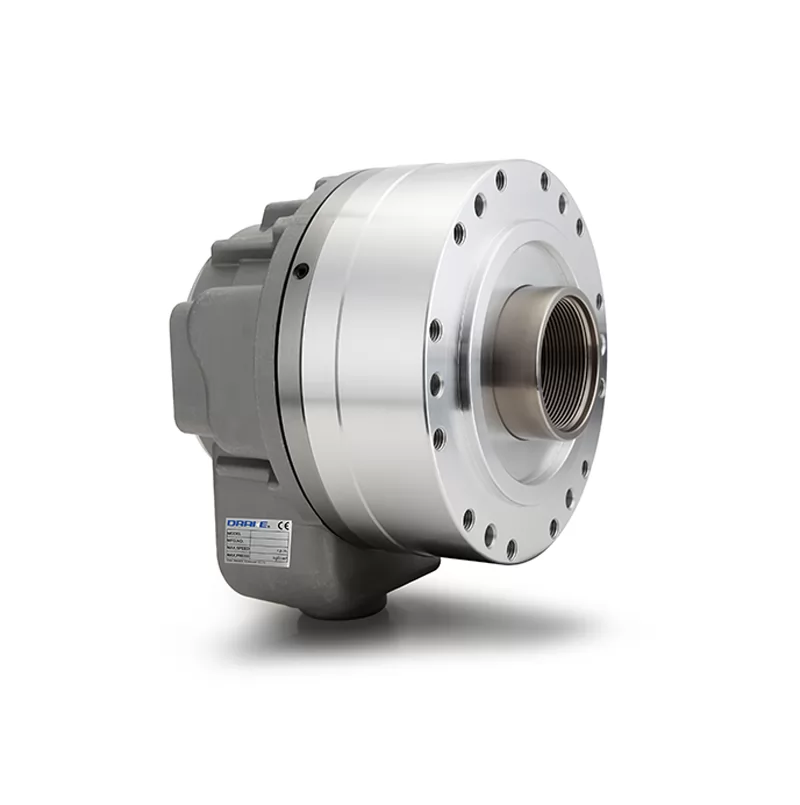

Bi-Directional Spindle Clamp Seat

The bi-directional spindle clamp seat is a high-precision mechanical component designed to provide stable, reliable clamping in both forward and reverse spindle rotation. Ideal for CNC machining centers and automatic tool changers, this component ensures consistent axial positioning, vibration resistance, and high clamping repeatability. Engineered with durability and performance in mind, it supports precision machining processes that require rigid and symmetrical clamping solutions.

Bi-Directional Spindle Clamp Seat Characteristics:

It can be processed at both ends simultaneously, with double efficiency of "zero" concentricity at both ends, greatly reducing the volume and cost. It is a special tool for shaft and tube machining and a higher speed design to perfectly solve various processing requirements. It greatly reduces the length of the spindle. For short material processing, retractable and knife-type designs solve the length limitation of the spindle and make automatic feeding at the rear easier. The configuration of extended head and the use of movable two-set spindle clamping completely solve the double-head machining of super-long workpiece. The latest cartridge clamp design is super-large clamping stroke, which perfectly solves the clamping problem of large tolerance workpiece. (Special clamp products can be designed separately for customer products and processing characteristics)

Bi-Directional Spindle Clamp Seat Application:

Two-end special turning machine, spindle, shaft and sleeve processing. It is widely used in automobile, electromechanical and other manufacturing industries involving shaft applications.

At Drake Machinery, we supply advanced spindle clamp seats with customizable specifications to meet the requirements of different spindle systems. With optimized structure and high-quality materials, our products offer superior performance in high-speed, heavy-duty, and automated machining environments. OEM and special design requests are welcome.

Partner with a professional machine tool fixture supplier for long-lasting, performance-driven solutions in your production line.

Read More

FAQ About Bi-Directional Spindle Clamp Seat

Q1: What is a bi-directional spindle clamp seat?

A: It is a precision mechanical component designed to clamp the spindle securely in both clockwise and counterclockwise directions, ensuring stability during high-speed machining.

Q2: What applications require bi-directional spindle clamping?

A: It is mainly used in CNC machining centers, automated tool changers, and machine tools that operate in both spindle rotation directions, especially in applications demanding high positional accuracy and repeatability.

Q3: What are the key features of your clamp seat?

A: Our clamp seat features high rigidity, smooth engagement, excellent wear resistance, and precise alignment under bidirectional load conditions. It is also customizable to match specific spindle systems.

Q4: Can you customize the clamp seat according to our spindle type?

A: Yes. We offer OEM customization based on your spindle specifications, drawing, or technical requirements.

Q5: What materials are used in the clamp seat?

A: We typically use high-strength alloy steel or hardened tool steel for long service life and consistent performance under heavy-duty conditions.

Q6: What is your delivery time and warranty policy?

A: Standard models may be in stock. For customized models, production usually takes 10–15 working days. All clamp seats are covered by a 12-month warranty under normal usage.

How can I help you?

We can solve any problem for you: quality, price, delivery time, shipping cost, after-sales service, etc.

Drake International Trade Co., Ltd (Export Platform)

Add.: Yaoguan, WuJin District, Changzhou, Jiangsu, China 213000

Contact Person: Joanna Zhou

Mobile/Whatsapp/Wechat: +8613815018181

Tel: +86 519 8385 6060

Email: joanna@drakecn.com

Read More