Product Details

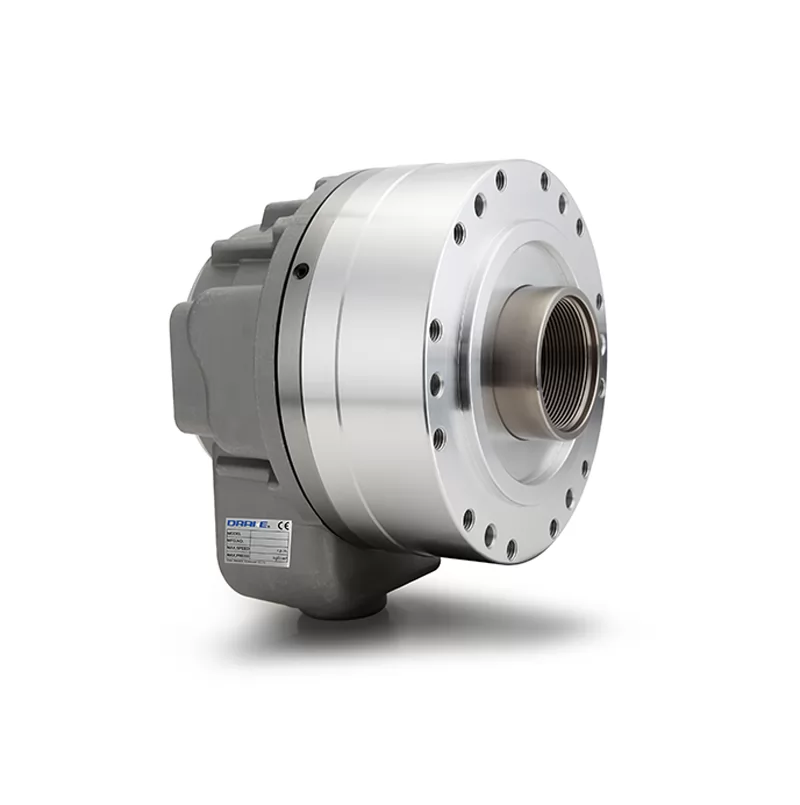

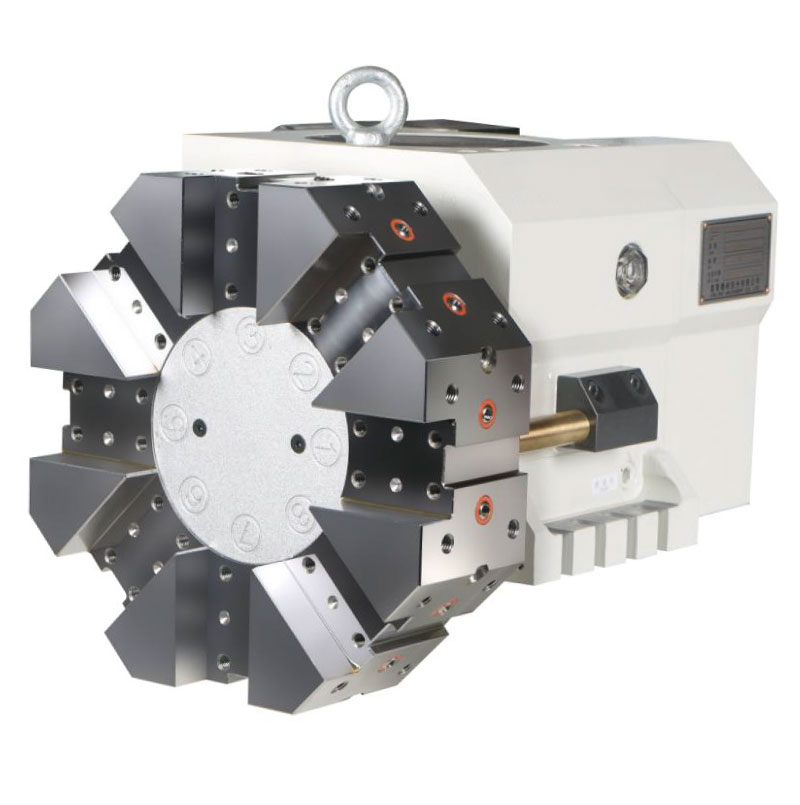

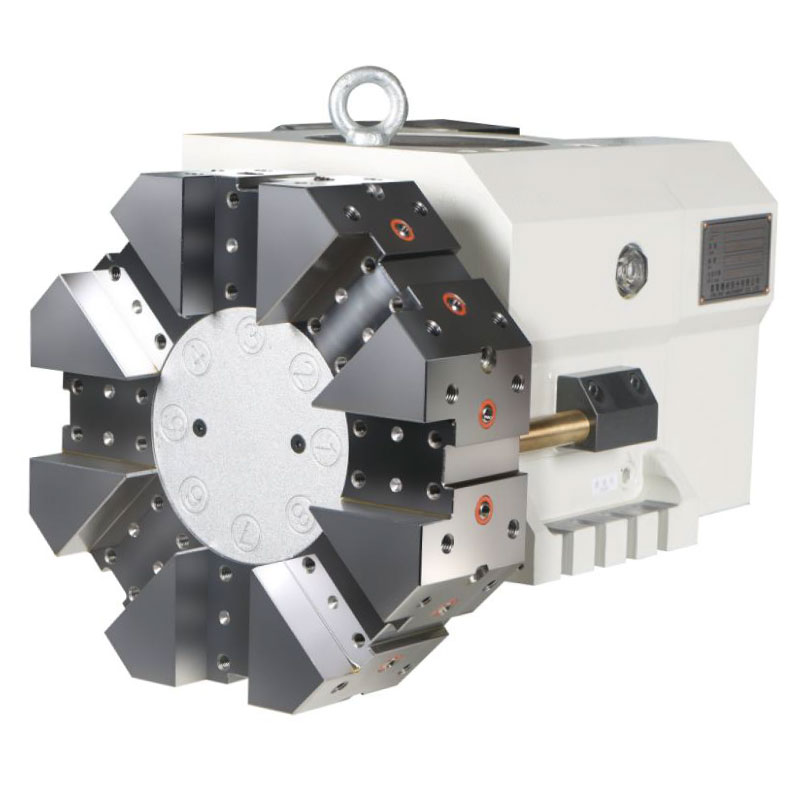

CLT series turret is a high-performance cam hydraulic turret designed for precision machining. This advanced CNC turret ensures efficient and stable tool changes, making it an ideal choice for various turning applications. With its robust hydraulic turret system and reliable servo turret control, it enhances machining accuracy and productivity. Whether for a lathe or a turning center, this lathe turret delivers exceptional performance in demanding industrial environments.

1. Inside mechanism employs cam, high indexing accuracy and fast tool change

2. Driven by hydraulic motor,high torque output and tools change stability.

3. Tool release clamping adopts hydraulic mechanism, reliable action, suitable for heavy cutting.

4. Controlled by proximity-detector and PLC programming, smart selection of nearby tools

5. Can be customized 30bar. 50bar. 70bar high pressure cooling。

The hydraulic turret plays a crucial role in the functionality of CNC machines, providing precise control and positioning. A well-designed hydraulic turret assembly is essential for seamless operations, as it integrates the turret rotation mechanism for accurate tooling placement.

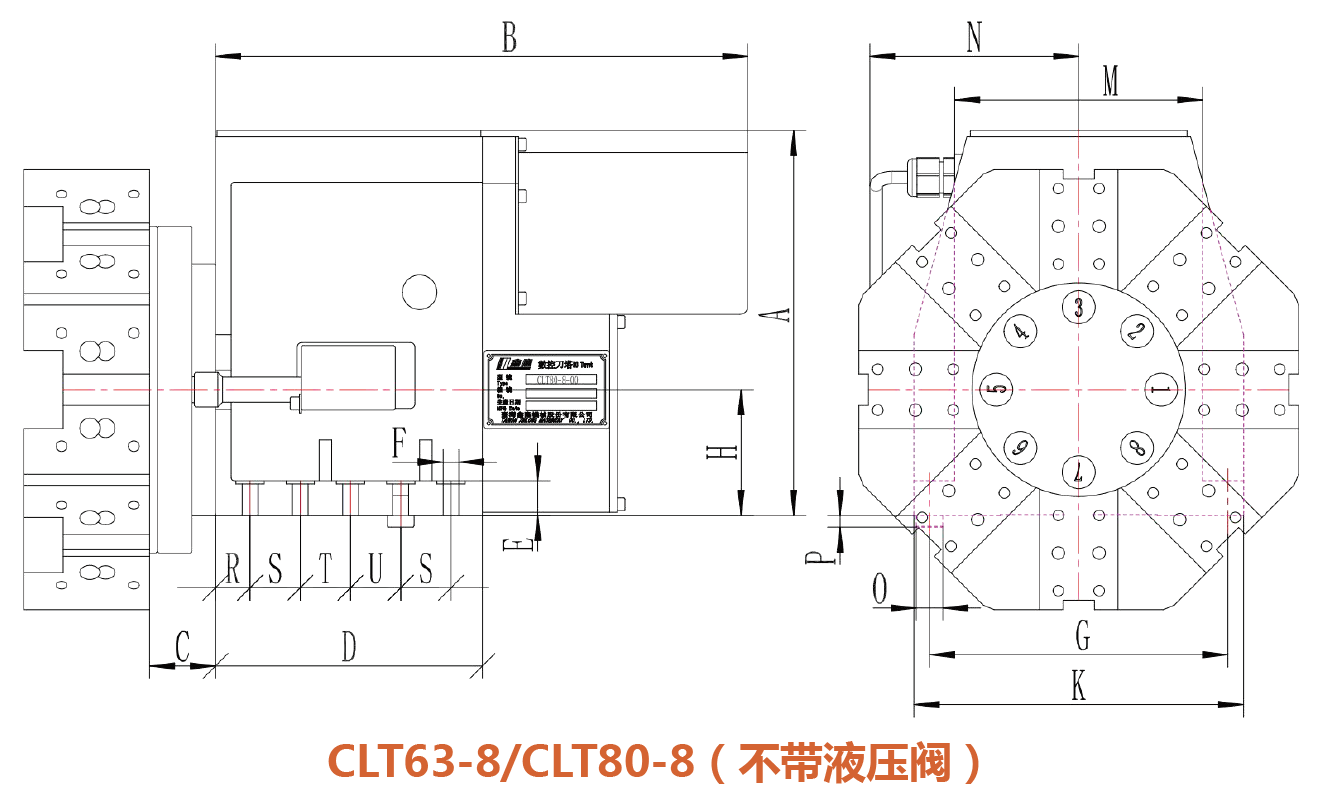

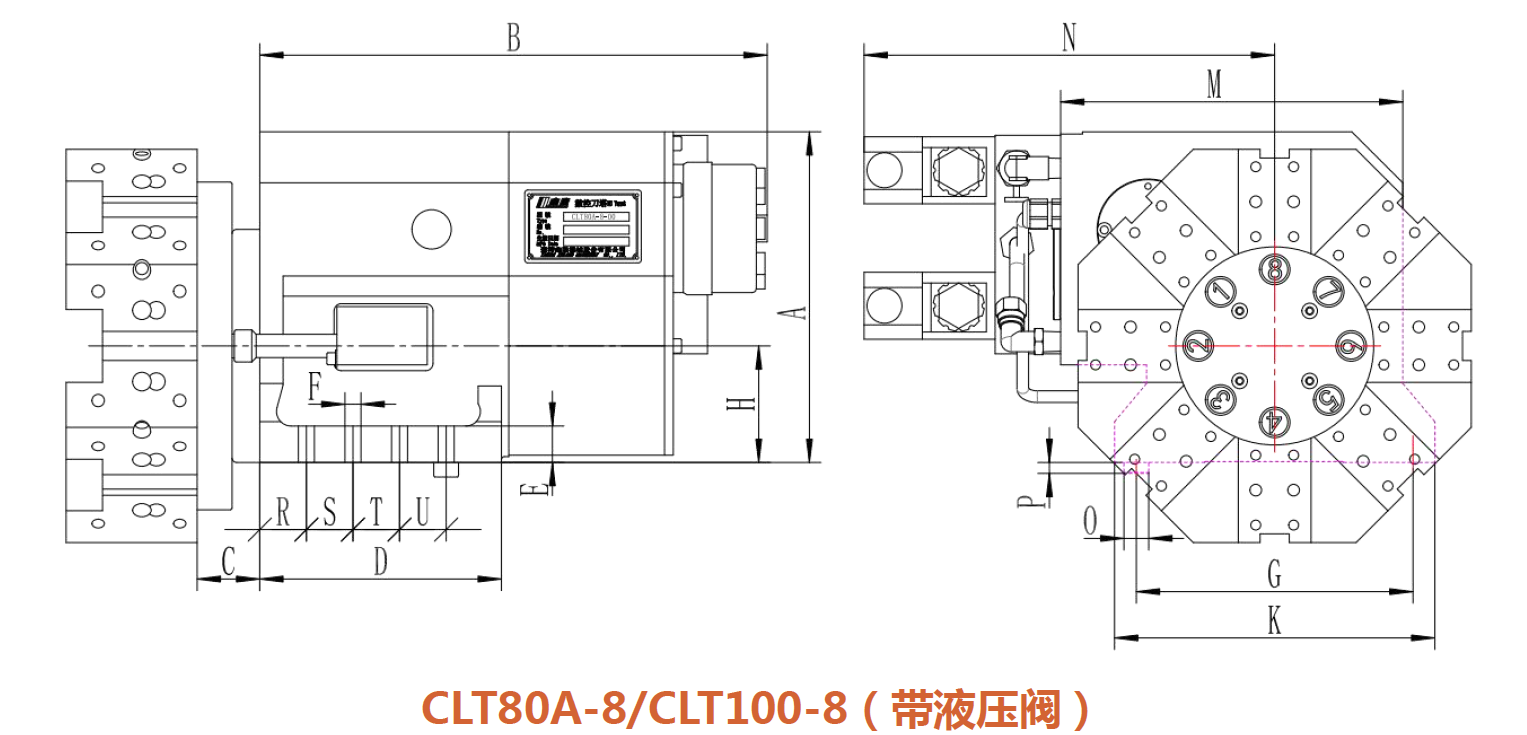

Product Size

Product Parameters

| Model | Dimension | ||||||||||||||||||||||||||||||||||||||||||||||||||

| H | A | B | C | D | E | F | G | K | M | N | O | P | R | S | T | U | |||||||||||||||||||||||||||||||||||

| CLT63-8 | 63 | 228 | 326 | 36 | 155 | 18 | 9- 11 | 165 | 185 | 146 | 99 | Φ15 | 8 | 19.5 | 30 | 30 | 30 | ||||||||||||||||||||||||||||||||||

| CLT80-8 | 80 | 245 | 339 | 42 | 170 | 22 | 10- 11 | 190 | 210 | 158 | 106 | Φ17 | 7.5 | 22 | 32 | 32 | 32 | ||||||||||||||||||||||||||||||||||

| CLT80A-8 | 80 | 227 | 349 | 43 | 166 | 25 | 8- 11 | 190 | 220 | 235 | 286 | Φ17 | 7.5 | 32 | 32 | 32 | 32 | ||||||||||||||||||||||||||||||||||

| CLT100-8 | 100 | 293 | 370 | 43 | 175 | 30 | 8- 13 | 220 | 250 | 272 | 307 | Φ20 | 9 | 34 | 40 | 30 | 30 | ||||||||||||||||||||||||||||||||||

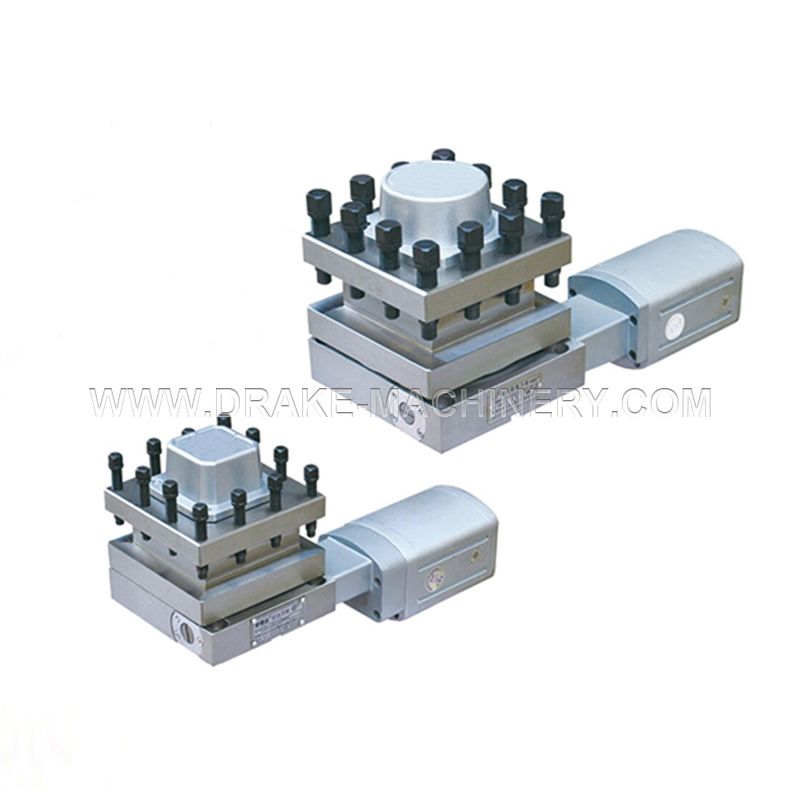

| Turret specifications And Accessories | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Model | CLT63 | CLT80 | CLT80A | CLT100 | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Opposites side | 8T | 228 | 280 | 270 | 330 | |||||||||||||||||||||||||||||||||||||||||||||||||

| 300 | 370 | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| 330 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12T | 340 | 340 | 380 | |||||||||||||||||||||||||||||||||||||||||||||||||||

| Boring Tool | Φ20 Φ25 Φ32 | Φ32 Φ40 | Φ32 Φ40 Φ50 | Φ40 Φ50 | ||||||||||||||||||||||||||||||||||||||||||||||||||

| O.D Tool | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Facing Tool | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| MAIN SPECIFICATIONS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Item | Parameter | Item | Parameter | |||||||||||||||||||||||||||||||||||||||||||||||||||

| Model | CLT63/80/80A/ 100A | Model | CLT63/80/80A/ 100A | |||||||||||||||||||||||||||||||||||||||||||||||||||

| Center height | mm | 63/80/80/ 100 | Working Flow rate | L/min | 18/22/25/30 | |||||||||||||||||||||||||||||||||||||||||||||||||

| Allowed number of tools | position | 8; 12 | Max unbalance moment of torque | Nm | 15/20/25/50 | |||||||||||||||||||||||||||||||||||||||||||||||||

| Rotation time | sec. | 0.35/0.35/0.4/0.65 | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Rotation and camping | sec. | 0.45/0.45/0.5/0.8 | Max tangential moment of torque | Nm | 1500/2000/2500/3500 | |||||||||||||||||||||||||||||||||||||||||||||||||

| Rotation time | sec. | 1.5/ 1.5/ 1.7/ 1.8 | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| Rotation and camping | sec. | 1.6/ 1.6/ 1.8/ 1.95 | Max axial moment of torque | Nm | 1500/2000/2500/3500 | |||||||||||||||||||||||||||||||||||||||||||||||||

| Repeatability Accuracy | ±1.6" | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| Indexing Accuracy | ±4" | Net weight (without tool disc) | Kg | 35/43/65/ 100 | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Working pressure | MPa | 3.5 | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Benefits of CLT Series Cam Hydraulic Turret

Multi-tool turning operations, where fast tool changes and stable indexing reduce non-cutting time.

Heavy cutting, roughing, or deep turning tasks requiring robust clamping and stability.

Medium- to high-volume production environments where consistency, repeatability and minimal downtime matter.

Mixed part production — when jobs require different tools or frequent tool swaps.

Situations where reliable, durable turret performance is essential for safety and productivity.

Applications of the CLT Series Cam Hydraulic Turret

CNC lathes for high-precision mass production of automotive components, fasteners, valves, and shaft parts.

Heavy-duty machining lines, where consistent indexing torque and strong clamping force are required to maintain cutting accuracy.

Medium-to-high speed metal cutting operations, supported by the turret’s robust structure and smooth tool change mechanism.

Custom CNC machines that demand long service life, low maintenance, and reliable mechanical performance.

Why Choose Drake as Your Hydraulic Turret Manufacturer

As a professional Hydraulic Turret Manufacturer, Drake provides turrets built for accuracy, rigidity, and long-term consistency. Each unit is assembled with strict quality control and tested for concentricity, rotational accuracy, and hydraulic responsiveness.

You benefit from:

● Smooth cam indexing for faster tool changes

● Rigid locking mechanism for improved surface finish

● Strong durability suitable for continuous operation

● Customizable configurations based on lathe type or production needs

Drake ensures a stable supply, technical support, and reliable after-sales service for global CNC machine builders and end users.

Looking for a dependable Cam Hydraulic Turret that enhances precision and productivity? Contact Drake today for pricing, specifications, and OEM/ODM support.