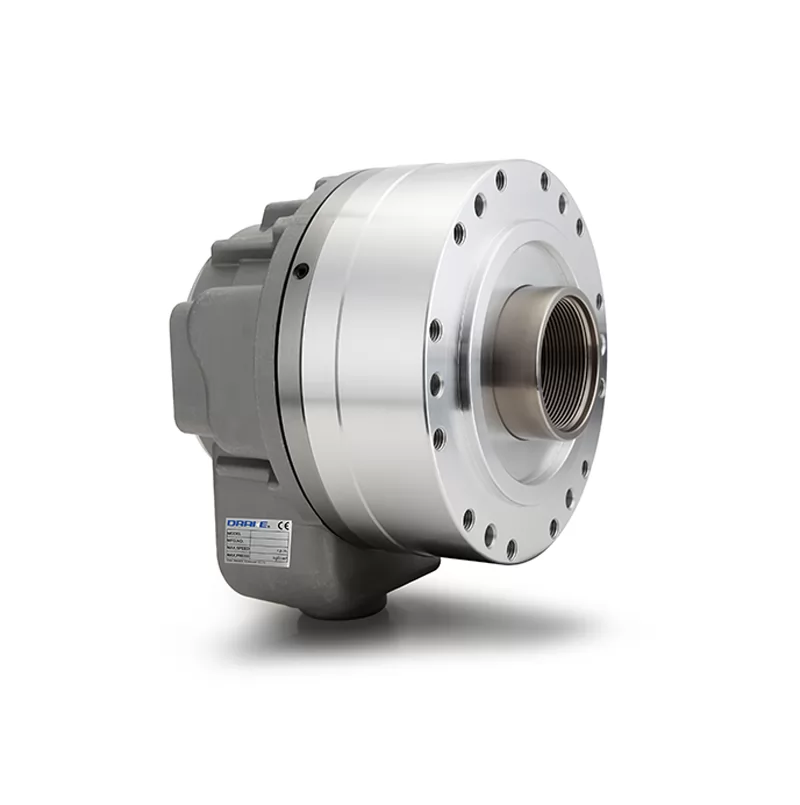

Collet Chuck

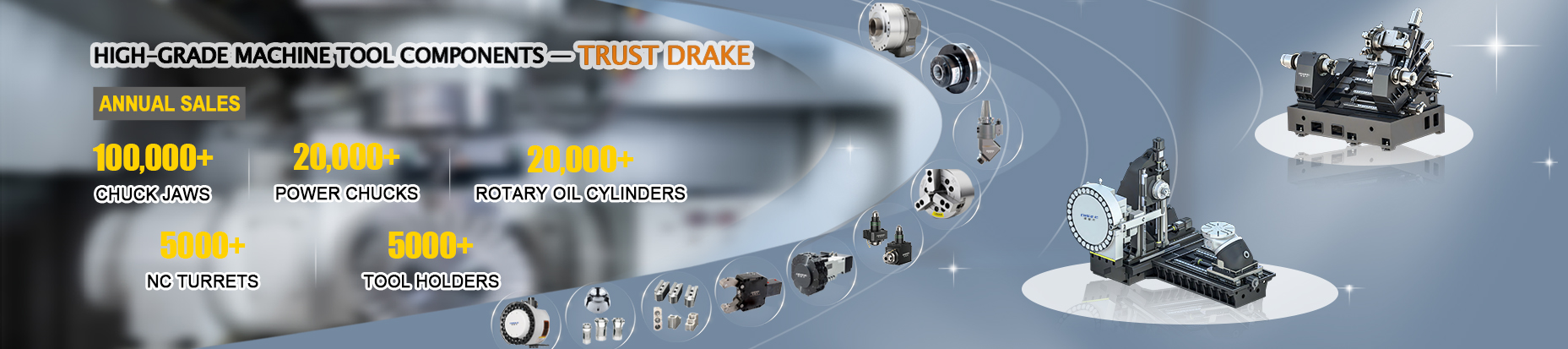

Drake precision technology (changzhou) Co.,Ltd. is a technology enterprise. In order to meet demands of the market, Drake is specialized in the research, development, production and sale of fixture. DRAKE manufactures high quality 2J CNC collets, 5C collets, 16C collets and 3J collets as well as many other sizes such as 1C collets and 3C collets.

DRAKE Collet Chuck

A Collet Chuck is a type of tool holder used in machining operations to hold workpieces securely in place while they are being machined. It is designed to grip the workpiece tightly and accurately, allowing for precise and efficient machining operations. The collet chuck is a preferred tool holder for applications that require high precision, such as milling, drilling, and reaming. A collet chuck is an essential tool in machining, widely used for holding workpieces or tools in both CNC lathe and manual lathe operations. When precision and repeatability are critical, a hydraulic collet chuck is often preferred for its ability to provide consistent clamping force, making it ideal for CNC collet chucks. There are various CNC collet types available, designed to meet the specific needs of different machining processes. For instance, a lathe collet chuck is specially engineered to securely hold cylindrical workpieces, which is crucial in CNC lathe operations. Leading collet chuck manufacturers offer a range of products that cater to the diverse demands of the industry, ensuring that machinists have the right collet chuck for lathe or CNC collet chuck to achieve high-precision machining tasks.

DRAKE can provide all the correct mounting adapters for spindles and rotary tables, as well as drawtube adapters, based on design information provided by the customer to fit your spindles, rotary tables and other machines. to suit your spindle, rotary table and drawtube requirements.

These precision lathe chucks will mount directly on American Standard (A4, A5, A6, A8) and Camlock (D4, D5, D6, D8) type spindles. DRAKE lathe chucks are also frequently used on cylindrical grinders, rotary tables and many other machines. The DRAKE Pneumatic Collet Chuck Assembly can be used to convert CNC lathes and grinders to workholding units with 16C, 2J, 3J and 5C collets.

These productivity enhancing CNC collet systems have built-in concentricity adjustment (less than 0.00050" TIR) and can be installed on all standard US spindles in less than 20 minutes. Only one complete lathe collet assembly is required, as each spindle adapter in the assembly accepts any DRAKE 16C, 2J, 3J and 5C collet adapters. The conversion is done quickly and easily by simply removing and replacing the six bolts on the collet adapter, which can also be used on Camlock-type spindles.

How does DRAKE make a collet chuck that satisfies you?

The manufacturing process of collet chuck can vary depending on the specific design and materials used, DRAKE usually follows the following steps to manufacture collet chucks for our customers.

Design: The first step in manufacturing a collet chuck is to design the product. This involves creating detailed drawings and specifications that define the size, shape, and material requirements for the chuck.

Material selection: Once the design is complete, the next step is to select the appropriate materials for the collet chuck. The chuck is typically made from high-quality steel or other durable metals that can withstand the rigors of machining operations.

Machining: The manufacturing process for a collet chuck involves a variety of machining operations, including milling, drilling, turning, and grinding. These operations are used to shape the various components of the chuck, including the body, collet, and locking mechanism.

Heat treatment: After the components have been machined, they are typically heat-treated to improve their strength and durability. This involves subjecting the components to high temperatures and then cooling them in a controlled manner.

Assembly: Once the components have been machined and heat-treated, they are assembled into a complete collet chuck. This involves fitting the collet into the chuck body and attaching the locking mechanism.

DRAKE has a high level of precision capability and a reservoir of expertise to ensure that the final collet chuck meets the stringent requirements of the machining operation.

Understanding the Accuracy of Collet Chucks

DRAKE Collet Chuck Benefits and Features

DRAKE's extensive line of CNC collet chucks offers many advantages over conventional 3-jaw lathe chucks - especially for workpieces less than 4" in diameter. Some of these advantages include:

Available in American Standard, Camlock and special spindle nose

CNC lathes for standard 16C, 2J, 3J and 5C collets, expansion collets and 5C step collets

Accepts 16C, 2J, 3J and 5C collet adapters per spindle mount

Built-in concentricity adjustment (below 0.00050" TIR)

Table driven by machine closures

Light weight allows for higher turning speeds

Balanced design for smooth operation

Easy and fast setup (less than 20 minutes)

Cartridges are unaffected by centrifugal forces

Small body diameter reduces tool interference

Continued cost reduction

DRAKE - Collet Chuck Manufacturer

We specialize in manufacturing collet chucks with production capacity, CE and ISO certifications, and dozens of patent certificates. Currently, we are in the process of applying for high-tech enterprise status. Having successfully secured bids from some of the world's top 500 enterprises, our workshop spans 15,000 square meters, and the company has invested over $20 million in state-of-the-art production equipment.

We have exported our products to more than 80 countries worldwide, backed by 10 years of export experience. Our strength lies in robust after-sales service and the capability to facilitate foreign trade orders.

Our standard products follow common installation methods aligned with international standards. They can serve as direct replacements for similar products from renowned brands.

We are equipped to accommodate customized products, accept orders for non-standard products, and welcome OEM orders.

Read More

FAQ About Collet Chuck

Q: What type of collet chuck can you provide?

A: We have hydraulic collet chucks and pneumatic collet chucks.

Q: What is the general clamping force range of the chuck?

A: The clamping force of the hydraulic chuck may be around 3000–5000N. The clamping force of pneumatic chuck is usually around 500–3000N.

Q: How long is the service life of the chuck generally?

A: The service life of the chuck is affected by various factors, including the material, manufacturing process, frequency of use, usage environment, and maintenance status of the chuck, so it is difficult to give an exact time.

Q: Do you provide compatible collet chucks?

A: The collet chuck needs to be purchased separately.

Q: What configurations can rotary pneumatic chuck provide?

A: This chuck can be used in either internal or external clamp configurations.

Q: What is the difference between front push and rear pull collet chucks?

A: The forward push chuck achieves clamping by pushing forward, using the front push rod to press the clamping claw against the workpiece. The pull back chuck achieves clamping by pulling backwards.

Pull back chucks typically offer higher positioning accuracy and repeatability, ideal for precision machining. Forward push chucks are widely used in situations requiring fast and convenient clamping without extremely high precision.

Q: How to choose a collet chuck?

A: The collet chucks are divided into: pneumatic collet chucks, hydraulic collet chucks, and vertical collet chucks.

Q: How to choose the chuck size?

A: What is the size of your workpiece?

Q: What is the delivery and warranty period?

A: The chuck body is in stock, but the collet needs to be customized according to the size of your workpiece. The production lead time is about 10–15 days, and the warranty period is 12 months.

Q: Can the accessories of collet chuck products be sold separately?

A: Collet and claw can be sold separately.

Q: Can I clamp a 10mm workpiece, and after working for a while, replace the chuck and clamp a 16mm workpiece?

A: Yes, it is one-to-one size.

Q: Can it be customized?

A: Can be customized according to your drawings.

Q: What accessories are there?

A: Installation screws and air nozzles, as well as collet wrenches.

Q: Can the matching collet be purchased separately?

A: Yes.

Q: Can you recommend a model?

A: Yes, please tell us the speed, clamping accuracy, whether to rotate, clamping force, and processing you need.

How can I help you?

Drake International Trade Co., Ltd (Export Platform)

Add.: Yaoguan, WuJin District, Changzhou, Jiangsu, China 213000

Contact Person: Joanna Zhou

Mobile/Whatsapp/Wechat: +8613815018181

Tel: +86 519 8385 6060

Skype: zhou.joanna9

Email: joanna@drakecn.com

Web: https://www.drake-machinery.com

Read More