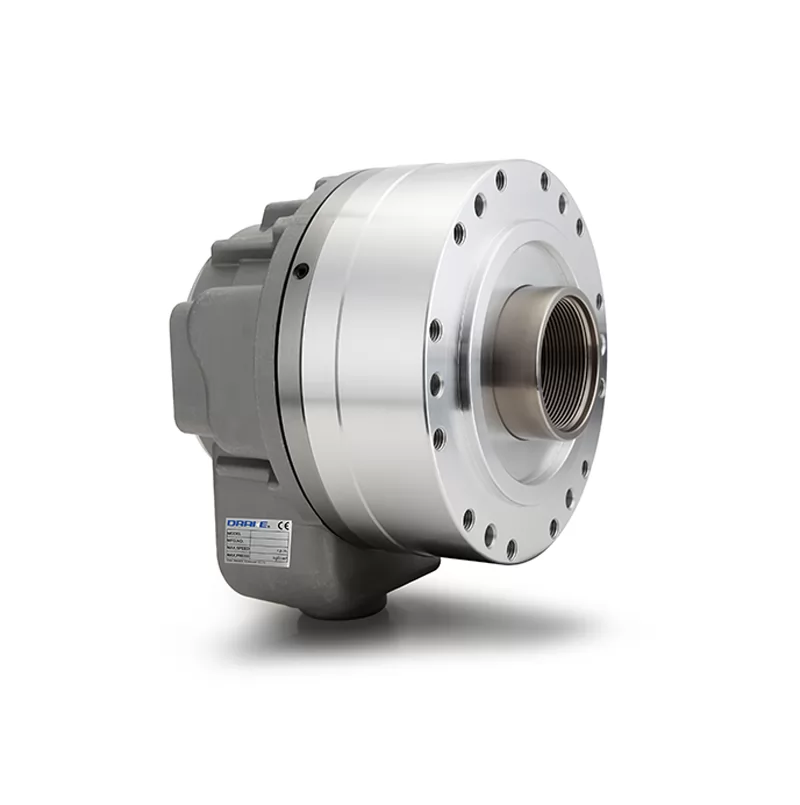

JAN ultra precision diaphragm bidirectional spindle holder - Double head lathe spindle holder

Product Details

Product Features:

● Adopt air pressure double diaphragm chuck design

● Double diaphragm bobbin clamp, the precision of clamp base body is 0.005mm, and the repeated clamping precision of workpiece is ≤0.01mm

● The maximum working pressure is 6kg/cm², Maximum speed ≤3000rpm/min

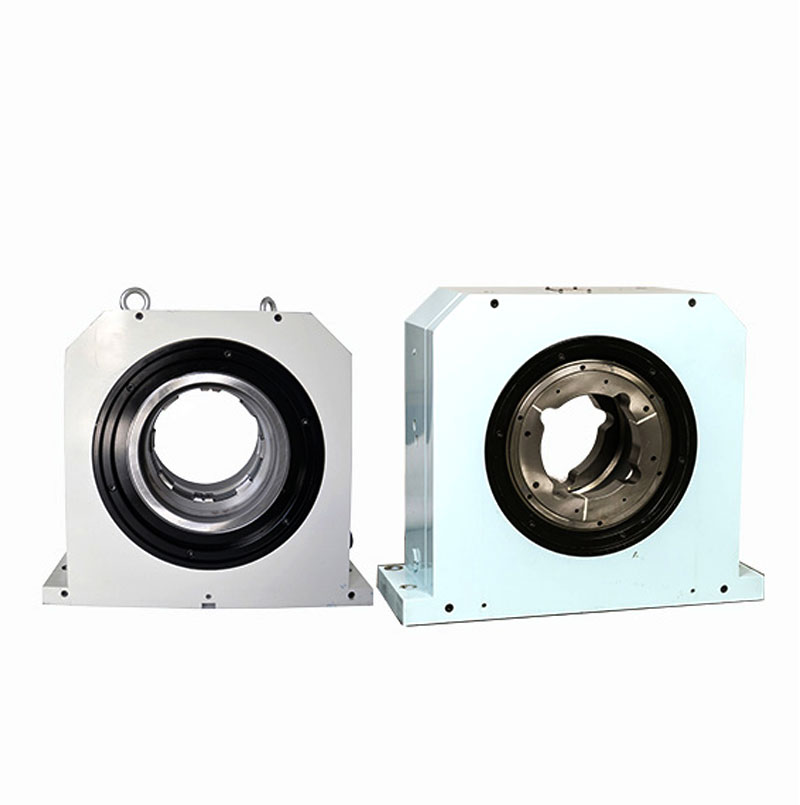

● The assembly of the clamp seat is shown in the figure, which can be designed horizontally as required, ≤45°, 90° installation,

● Piston area: 85-140cm² The piston moves inward, and the workpiece is clamped. The piston stroke is 3mm, and the clamping stroke is 0.3mm

● Concentric datum at "0" position ensures concentricity.

● Composite waterproof mechanism design ensures waterproof performance

● Different clamping methods can be made according to the workpiece and processing

Product Application:

● It is widely used as a special tool for precision shaft and tube processing, such as special machine for rotary cutting at both ends, precision spindle, shaft sleeve, printing and copying machine shaft, etc

Product Size

None

Product Parameters

| Product Model | Product Parameters | ||||||||||||||

| A | B | C | D | E | F | G | H | I | J | K | L | M | N pulley | Adapt to bobbin clamp | |

| JAN-70 | 155 | 280 | 240 | 88 | 30.5 | 180 above | 36 | 75 | 163 | 320 | 280 | 100 | 60 | 64 gear-8M | JD-70 |

| JAN-100 | 155 | 280 | 240 | 88 | 33.8 | 205 above | 53.3 | 105 | 189 | 320 | 280 | 100 | 60 | 74 gear-8M | JD-100 |

| JAN-150 | 155 | 280 | 240 | 88 | 37 | 220 above | 50 | 155 | 227 | 320 | 280 | 100 | 60 | 90 gear-8M | JD-150 |