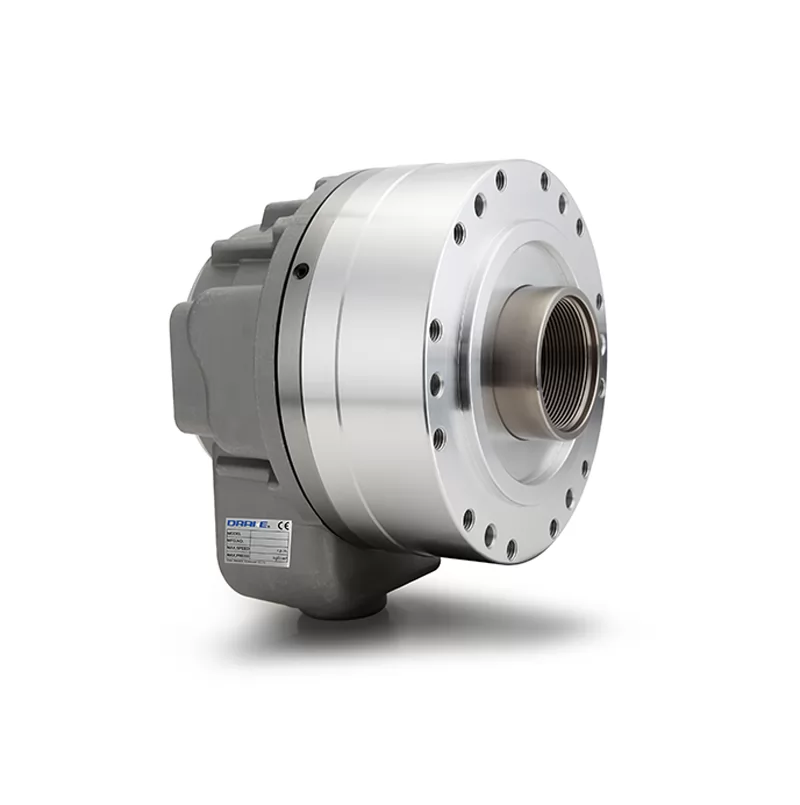

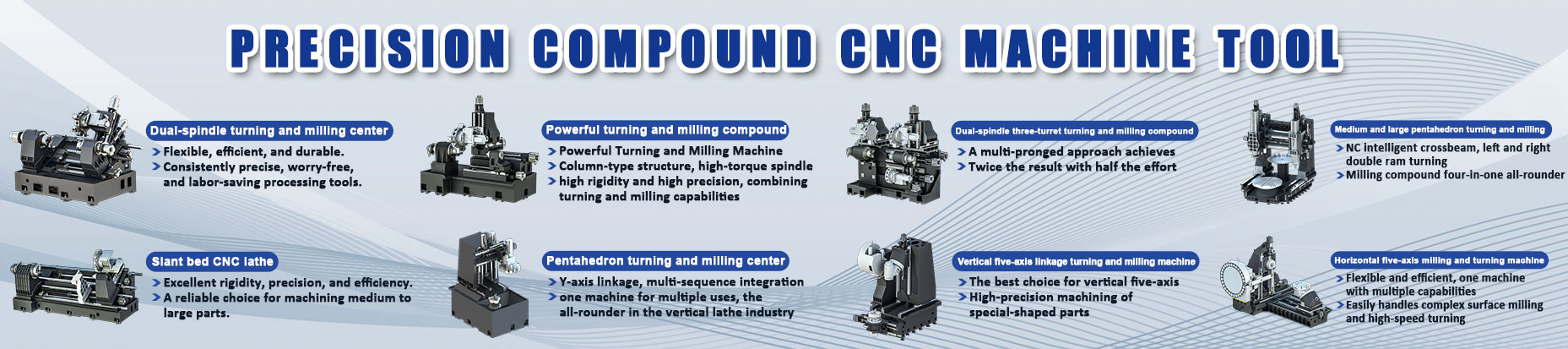

Product Details

Looking for a turning centre that delivers precision, rigidity, and high-speed performance? Our 45-mm Single Spindle, Single Turret, Single Y-Axis Turning Centre with optical feedback and linear rails is engineered for demanding applications. Whether you’re machining complex parts or aiming for tight tolerances, this machine gives you the control and durability you need.

Product Advantages:

Exceptional Rigidity & Accuracy — Linear rail guidance and optical systems ensure minimal deflection and maximum positional repeatability.

Improved Productivity — Single spindle + single turret + Y-axis design for efficient multitasking with reduced set-ups.

Reduced Maintenance, Longer Life — High-quality components built for durability; optical sensors and rails designed for simplified calibration and upkeep.

Customization Options — Tailor the configuration (turret type, tooling, control system) to your specific production workflow.

Product Size

| ltem | Size | GP-400Y | |||||||||||||||||||||||||||

| Working range | Max.Turning diameter over bed | φ580 | |||||||||||||||||||||||||||

| Max.Turning swing dia over carriage | φ330 | ||||||||||||||||||||||||||||

| Max.Turing diameter | φ250(When the X, Y axis and power tool turret are protected as a whole) | ||||||||||||||||||||||||||||

| Max.length between chuck and tailstock cente | 500 | ||||||||||||||||||||||||||||

| Max.Processing length | 450 | ||||||||||||||||||||||||||||

Max,X/Z axis rave | Xaxis | 230 | |||||||||||||||||||||||||||

| Yaxis | 120 | ||||||||||||||||||||||||||||

| Z axis | 530 | ||||||||||||||||||||||||||||

| R axis(Tailstock travel) | 530 | ||||||||||||||||||||||||||||

| Feed screw | Controlaxis | 5Axis(X2+Y2+Z2+R+C1) | |||||||||||||||||||||||||||

| Xaxis ball-screw | 3208-C3 | ||||||||||||||||||||||||||||

| (N·m)Recommend the X axis motor torque | >10 | ||||||||||||||||||||||||||||

| Y axis ball-screw | 3208-C3 | ||||||||||||||||||||||||||||

| (N·m)Recommend the Y axis motor torque | >10 | ||||||||||||||||||||||||||||

| Zaxis ball-screw | 3208-C3 | ||||||||||||||||||||||||||||

| (N·m)Recommend the Zaxis motor torque | >15 | ||||||||||||||||||||||||||||

| R axis ball-screw | 3208-C3 | ||||||||||||||||||||||||||||

| (N·m)Recommend the R axis motor torque | >10 | ||||||||||||||||||||||||||||

| Bed slant angle | 45° integral casting bed | ||||||||||||||||||||||||||||

| Linear guide's span | 400 | ||||||||||||||||||||||||||||

| Spindle | (rpm)Max.spindle speed | 4500 | |||||||||||||||||||||||||||

| Spindle through-hole diameter | φ61 | ||||||||||||||||||||||||||||

| Spindle nose size | A2-6 | ||||||||||||||||||||||||||||

| (KW)Recommend the spindle motor power | 7.5 | ||||||||||||||||||||||||||||

| Hydraulic Tailstock | Diameter of Tallstock center sleeve | φ80 | |||||||||||||||||||||||||||

| Max.stroke of Tailstock center sleeve | 120 | ||||||||||||||||||||||||||||

| Taper of Tailstock center sleeve | MT4 | ||||||||||||||||||||||||||||

Product Parameters

FAQ:

Q: Do you have optical machines that comply with VMC or repair machine frames?

A: We have wire or hard rail milling composite machines.

Q: Can you provide the corresponding accessories?

A: We can provide the relevant accessories, such as turret and tool holders.

Q: How to choose the appropriate optical machine according to your needs?

A: Firstly, it is necessary to clarify the application scenario and specific requirements. In addition, factors such as the size, weight, and interface type of the optical machine need to be considered to ensure that it can be used in conjunction with other devices.

Q: What factors affect the stability of optical machines?

A: The stability of optical machines is influenced by various factors, including the rigidity of mechanical structures, the thermal stability of materials, changes in environmental temperature and humidity, vibration, etc.

Q: What method of transportation do you use?

A: Generally by sea.

.jpg)

-gp-400s.jpg)

-gp-360-dp-400.jpg)

-gp-500.jpg)

-gp-630sy.jpg)