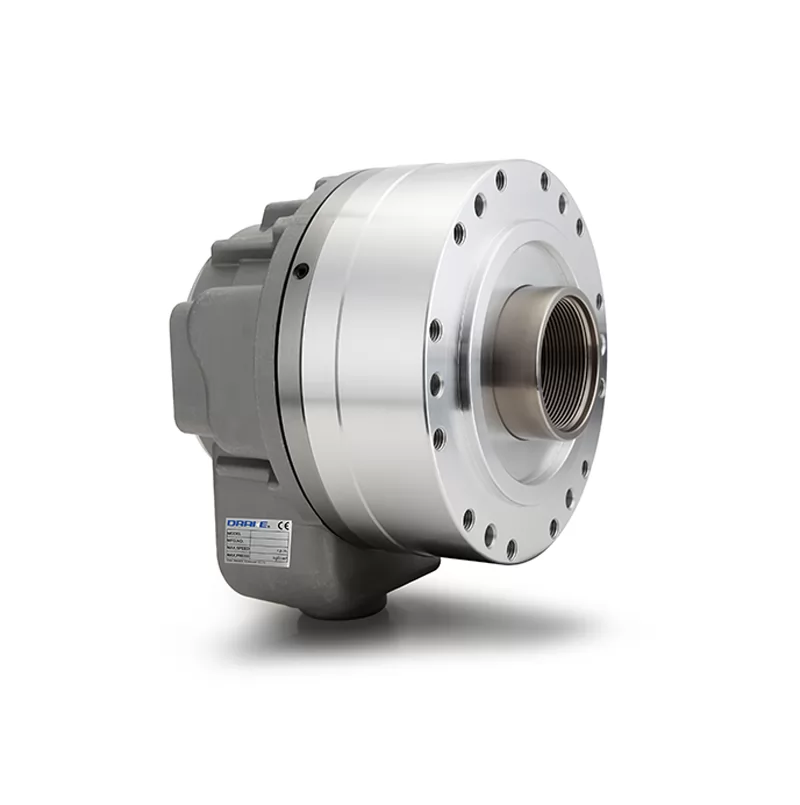

Rotary Cylinder

Our rotary cylinder is a reliable and efficient solution for converting fluid pressure into rotary motion. It features a high-quality design with a durable internal piston or rotor, which enables smooth and precise rotation. The cylinder is available in various sizes and configurations to meet the specific needs of your application. Rotary cylinders are mainly used in NC lathes as a drive for power chucks. In addition to rotary cylinders, we offer an extensive line of power chucks.

How Does A Rotary Cylinder Work?

Rotating Hydraulic Cylinder

Our rotary hydraulic cylinder is a powerful and versatile option for converting hydraulic pressure into rotary motion. It features a robust design with high-strength materials that can handle even the most demanding applications. The cylinder is available in a variety of sizes and styles to suit your specific needs, and it can be customized with additional features such as adjustable stroke length and position sensing. Our rotary hydraulic cylinder is an ideal choice for use in heavy machinery, construction equipment, and other high-load applications.

A rotating hydraulic cylinder is a highly engineered and precisely manufactured device that must meet rigorous specifications and standards to ensure reliability, durability, and performance.

A Drake rotating hydraulic cylinder is designed to meet specific requirements and specifications of the end-user. Drake designs cylinders taking into account factors such as load capacity, rotational speed, operating pressure, temperature and environmental conditions.

The Drake cylinder itself is typically made from high-quality materials, such as steel or aluminum, to ensure strength, durability, and corrosion resistance. The piston is designed to fit precisely within the cylinder, providing a tight seal to prevent hydraulic fluid from leaking out.

The shaft of the hydraulic cylinder is attached to the piston and rotates when hydraulic pressure is applied. Drake will ensure that the shaft is strong enough to handle the load capacity and rotation speed required by the end user.

The hydraulic system that powers the cylinder is also an important consideration for the Drake. The system must be designed to deliver the necessary pressure and flow rate to the cylinder while maintaining efficiency and reliability.

In addition to design and engineering, the Drake must also ensure that the cylinder is manufactured to the highest quality standards. This includes using advanced manufacturing techniques and equipment, as well as thorough testing and inspection processes to ensure the cylinder meets all specifications and requirements.

How can I help you?

Drake International Trade Co., Ltd (Export Platform)

Add.: Yaoguan, WuJin District, Changzhou, Jiangsu, China 213000

Contact Person: Joanna Zhou

Mobile/Whatsapp/Wechat: +8613815018181

Tel: +86 519 8385 6060

Email: joanna@drakecn.com

Read More

Rotary cylinders are essential hydraulic components that convert fluid pressure into rotary motion. They are widely applied in CNC lathes, power chucks, automation systems, and other precision machinery. As a leading Rotary Cylinder Manufacturer, Drake offers high-performance solutions designed for reliability, safety, and long service life.

Key Features of Drake Rotary Cylinders

High-Speed & Short-Stroke Models – Ideal for compact setups requiring fast response and efficient operation.

Built-in Safety & Control Systems – Equipped with stroke control, proximity sensors, check valves, and pressure relief valves for stable performance.

Coolant, Air, and Through-Hole Options – Designed for long-shaft machining and applications requiring coolant or compressed air supply.

Independent Oil Drain Outlet – Prevents backpressure issues, ensuring smooth operation and extended component life.

Why Choose a Reliable Rotary Cylinder Manufacturer?

Choosing the right rotary cylinder manufacturer directly impacts machine efficiency, operational safety, and long-term costs. Drake stands out with its ability to provide:

● High responsiveness with advanced sealing and lubrication technology.

● Enhanced safety systems with monitoring and control features.

● Customizable specifications to meet different industries’ unique requirements.

● Low-maintenance design for easy part replacement and reduced downtime.

As industries demand greater accuracy and efficiency, rotary cylinders have become indispensable in modern machining. With Drake’s expertise as a Rotary Cylinder Manufacturer, customers can rely on durable, efficient, and customizable solutions tailored to their production needs. Contact Us Now!

FAQ

Q: What materials are used for the cylinder barrel and piston rod respectively? What processing techniques have been used?

A: The cylinder barrel is made of high-quality carbon steel, which has undergone quenching and tempering treatment and precision honing. The piston rod is made of 40Cr alloy steel, which has undergone quenching and chrome plating treatment, making it wear-resistant and corrosion-resistant.

Q: How is the sealing performance?

A: It has good sealing and oil resistance, no leakage risk under rated pressure, and a long service life.

Q: Do you have bulk purchase discounts?

A: Discounts can be given for bulk purchases based on the order quantity, and specific details can be negotiated.

Q: Has the product passed the relevant quality certification?

A: Our products have obtained ISO 9001 quality management system certification, CE certification, etc. to ensure that the product quality meets international standards.

Q: What are the available installation methods?

A: Supports various installation methods such as flange type and base type, adapting to different mechanical equipment requirements.

Q: How to choose a cylinder?

A: Cylinders are divided into: 1. Hydraulic cylinders and pneumatic cylinders; 2. Solid cylinders and hollow cylinders.

Q: How do you know whether you want a hollow or solid cylinder?

A: 1. Is your chuck hollow or solid? 2. Do you need to see if your workpiece passes through the cylinder?

Q: What is the delivery and warranty period?

A: 4-15 inch cylinder are in stock and shipped as normal. The warranty period is 12 months.

Read More