Tool magazine

Tool Magazine in CNC Machining Centers

The tool magazine system is a storage and tool-changing device required for the automation of CNC machining center processes. Its automatic tool-changing mechanism and tool magazine capable of storing multiple tools have revolutionized traditional, manual production methods. Controlled by computer programs, it accomplishes various machining requirements such as milling, drilling, boring, and tapping, significantly reducing processing time and production costs—this stands as the key feature of the tool magazine system. Get in touch with us today to discuss your needs!

Key Components of a Tool Magazine:

Carousel or Tool Changer:

This component stores and positions cutting tools. During tool change operations, it rotates to present the required tool to the spindle.

The number of tools that can be stored in the carousel varies based on the machine size and manufacturer, ranging from 10 to 200 tools.

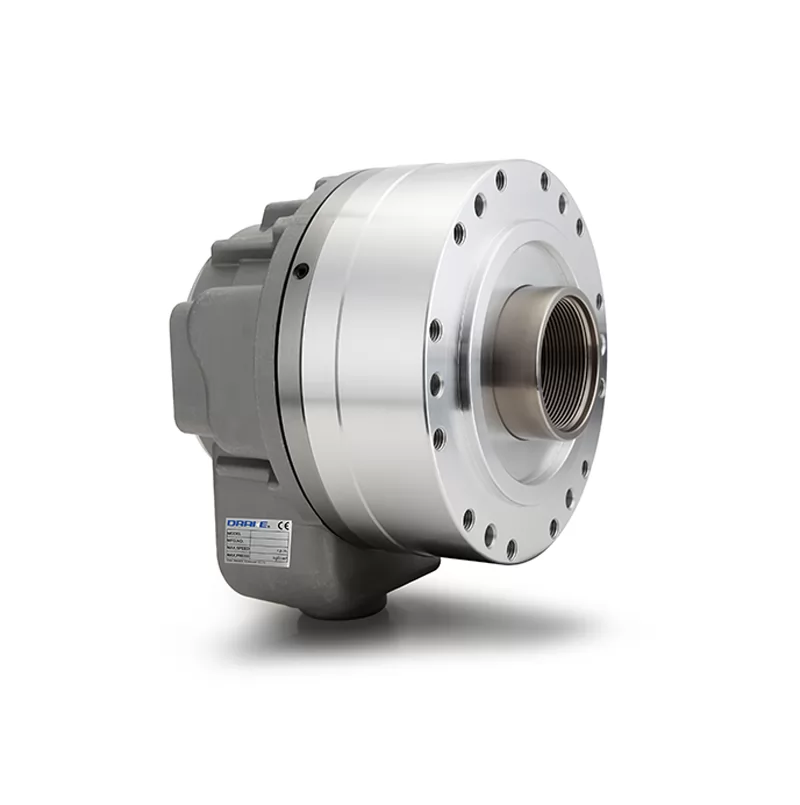

Tool Holder or Chuck:

The tool holder serves as the interface between cutting tools and the spindle, firmly securing the tool in place during the machining process.

Clamping Arm or Tool Change Arm:

Responsible for picking up tools and positioning them into the spindle or tool holder, ensuring a secure fixture to prevent any movement during processing.

Controller:

The controller acts as the brain behind the tool change operation sequence, receiving commands from the machine's CNC program.

It coordinates the rotation of the carousel, clamps the required tool, moves it to the desired position, and releases it into the spindle or tool holder.

Carousel Type Tool Magazine:

Typically, it can store 16 to 24 tools, and the entire magazine moves to the spindle during tool changes.

The magazine rotates when the spindle moves up, allowing the tool on the spindle to enter the magazine slot.

Once the tool to be changed is directly below the spindle, the spindle moves down, and the tool enters the spindle taper hole.

After clamping, the magazine returns to its original position.

Inverter Type Vertical Disc Tool Magazine:

Commonly used in small vertical machining machines.

The disc magazine, also known as the "disc magazine," has a smaller capacity, usually holding two to thirty tools.

Tool exchange is executed with Auto Tools Change (ATC).

Tool magazine types and features

Read More

DRAKE CNC Tool Magazine

Increased Speed: Designing tool magazines with faster rotation speeds to reduce tool change time and enhance machine speed.

Greater Tool Capacity: Increasing the tool magazine capacity to handle more critical and complex components without the need for frequent reloading.

Enhanced Flexibility: Growing demand for tool magazines capable of handling various types of cutting tools (e.g., drills, end mills, taps, and reamers) without compromising performance. This approach, known as universal tooling, significantly reduces manufacturing costs, boosts productivity, and improves precision.

Drake is a leading enterprise with 15+ years of factory experience, specializing in machine tool accessories and offering OEM & ODM services. We cooperate with over 60 countries and provide one-stop purchasing solutions for for Power Chuck, Collet Chuck, Turret, Tool Holder, Rotary Cylinder, Laser Chuck, Tool magazine, and more. Our strict adherence to international quality standards and comprehensive product range ensures tailored processing solutions for diverse customer needs.

Tool Magazine FAQ

Q1: What station numbers are available for your tool magazine?

A1: We generally offer tool magazines with 8, 10, 12, 16, and 20 stations.

Q2: Does the tool magazine include a bracket?

A2: The bracket is not included by default. It needs to be purchased separately and customized based on the customer's machine model and layout requirements.

Q3: Is the tool changing mechanism of the hat-type tool magazine manual or pneumatic?

A3: It is pneumatic.

Q4: What should I pay attention to when installing tools into the tool magazine?

A4: Ensure the tool shank matches the tool holder clamp in the magazine, and the installation accuracy meets technical requirements. Insert the tool correctly into the chuck and secure it using the designated clamping mechanism.

Q5: What is the tool change time for the magazine? Can it perform quick tool changes?

A5: The tool change time for a single tool is approximately 3TC. With dual robotic arms and high-speed transmission mechanisms, the magazine can achieve efficient and rapid tool changes.

Q6: Does the quoted price include installation and debugging?

A6: No, the quotation does not include free installation and debugging. However, we provide online technical guidance to ensure proper equipment operation.

How can I help you?

Drake International Trade Co., Ltd (Export Platform)

Add.: Yaoguan, WuJin District, Changzhou, Jiangsu, China 213000

Contact Person: Joanna Zhou

Mobile/Whatsapp/Wechat: +8613815018181

Tel: +86 519 8385 6060

Skype: zhou.joanna9

Email: joanna@drakecn.com

Read More