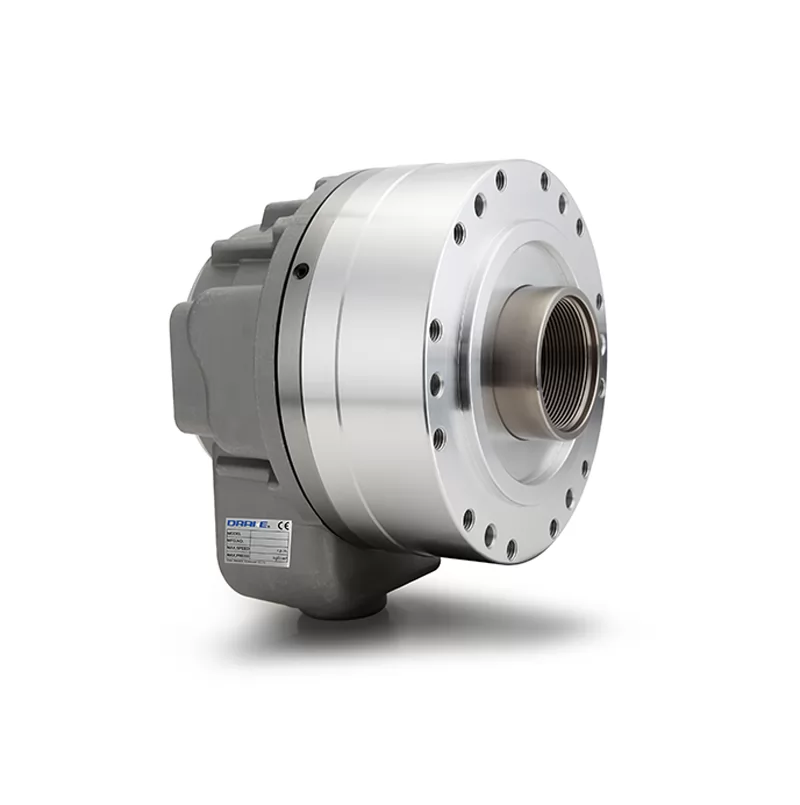

Hydraulic Center Rest

As a leading Hydraulic Center Rest Manufacturer - Drake, we deliver advanced hydraulic steady rest solutions engineered for high-precision turning applications. Our hydraulic center rests are designed to provide stable, automatic and accurate support for long or slender shafts — ensuring consistent concentricity, reduced vibration, and safe machining even under demanding conditions.

Read More

As a leading Hydraulic Center Rest manufacturer, Drake delivers superior stability, accuracy, and quality for industrial machining applications worldwide.

Why Choose Drake Hydraulic Center Rest

Automatic Self-Centering & High Stability: Drake’s hydraulic center rest uses a hydraulic cylinder to drive the clamping mechanism, enabling automatic self-centering and uniform pressure on the workpiece. This ensures the workpiece remains concentrically aligned with the spindle axis, supports long shafts and prevents bending or deflection during turning.

Improved Machining Accuracy & Surface Finish: By minimizing vibration and stabilizing the workpiece, our steady rest delivers enhanced dimensional accuracy, smoother surface finish, and reduces tool wear — essential for precision components and tight-tolerance parts.

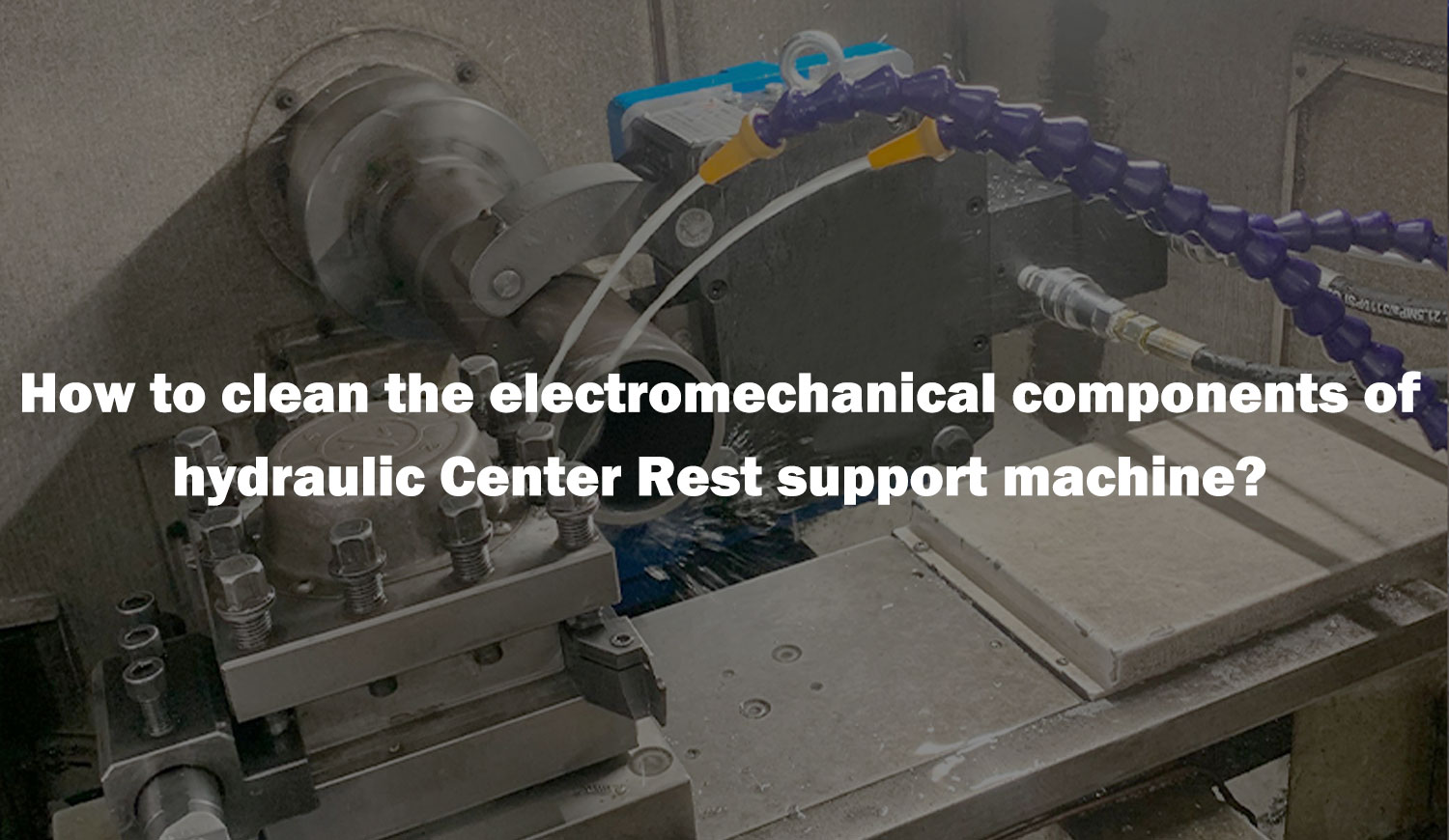

Support for Long, Slender Workpieces: Hydraulic center rest allows you to machine long tubes, shafts or rods that are too flexible or unstable for chuck alone. It stabilizes mid-span sections, making long-length turning, boring or facing operations possible and safe.

Versatile Compatibility & Easy Integration: Suitable for use with CNC lathes or manual turning machines, our center rest can be positioned along the bedway as required. Its design supports variable diameters and workpiece lengths, making it ideal for general turning, shaft machining, tube processing, and custom metalworking jobs.

Enhanced Safety and Operator Confidence: Compared to manual steady rests that require manual adjustment and carry risk of misalignment, Drake’s hydraulic solution ensures consistent clamping pressure and alignment — greatly reducing the risk of workpiece shift or accidents during rotation

Typical Applications & Use Cases

Precise turning of long shafts, tubes, and rods where support is needed mid-span

Boring, facing, or machining sections far from the chuck where deflection or vibration may occur

High-precision part production in CNC or conventional lathes

Maintenance, repair, and fabrication of long cylindrical components

Batch production where repeatability, quality consistency, and operator safety are essential

Key Value for Your Workshop or Factory

By investing in a Drake hydraulic center rest, you gain:

● Better workpiece stability, resulting in more accurate, concentric parts

● Reduced vibration and tool chatter, leading to smoother surface finish and longer tool life

● Ability to machine longer, slender parts safely and effectively

● Higher throughput and lower scrap rate — improving productivity and ROI

● Greater operator safety and lower risk of run-out or workpiece damage

Order Your Hydraulic Center Rest Solution Now

Read More