Nov. 20, 2025

The spindle of a CNC vertical lathe is perpendicular to the horizontal plane, and it has a large-diameter circular worktable for clamping workpieces.

This type of machine tool is mainly used for machining large, complex parts with large radial dimensions and relatively small axial dimensions.

CNC Vertical Lathe Stopping Fault Symptoms: The vertical CNC lathe makes a loud noise when stopping, and the workshop's main power supply trips simultaneously.

First, the workshop electrician inspected the power supply system. Due to the humid environment,

the automatic circuit breaker's tripping linkage mechanism inside the switch box was corroded. Additionally,

only a small portion of one of the three-phase contacts was making contact. Secondly, the workshop's power transformer had insufficient capacity and was operating under overload;

its normal phase voltage was only 340V. Finally, one of the CNC vertical lathe's thyristors was burnt out. Inspection of the drive circuit revealed that the trigger pulse was short,

only one-quarter of the normal trigger pulse amplitude, further investigation confirming that the problem was caused by a faulty amplifier transistor in the trigger circuit.

Vertical CNC Lathe Fault Analysis:

The consequences of a phase loss in thyristor operation differ between rectification and inversion modes. In rectification mode,

the thyristor with the higher trigger potential is always activated, simultaneously causing the preceding thyristor to be turned off by a reverse voltage.

During the thyristor's turn-off period, it is primarily in a reverse blocking state. Even if the subsequent thyristor is not activated,

it will automatically turn off at a certain point due to zero crossing. However, during deceleration (i.e., in inversion mode),

the thyristor with the higher trigger potential is activated, causing the preceding thyristor to be turned off by a reverse voltage. In this case,

the thyristor remains in a forward blocking state for a considerable period during turn-off.

Therefore, if the subsequent thyristor does not activate, due to the discharge effect of the inductor, it will continue to conduct for another cycle,

entering the positive half-cycle. This thyristor will continue to conduct, simultaneously preventing the subsequent thyristors from conducting.

Therefore, the positive voltage output by the thyristor and the electric potential of the motor combine to generate a large current, which causes inverter failure.

This can result in anything from a blown fuse to a burnt-out thyristor. If the voltage supply system of the CNC vertical lathe workshop is normal and without significant fluctuations,

the thyristor may not burn out. However, the failure was caused by a combination of factors, including large fluctuations in the AC grid voltage,

the workshop transformer's small capacity and overload operation, the small amplitude of the B-phase positive trigger pulse, and damage to the main switch box of the workshop's power supply system.

Troubleshooting Methods for Vertical CNC Lathes:

1. Replace the automatic air circuit breaker.

2. Replace the thyristors.

Experience-Based, High-Precision and High-Efficiency.

The HTC16-5/6/8 series CNC horizontal gang tool lathe is a small-scale CNC product designed and manufactured to meet market demands,

incorporating our factory's years of CNC lathe production technology and experience. This machine tool is economical, efficient, energy-saving,

has high positioning accuracy, and is easy to maintain.

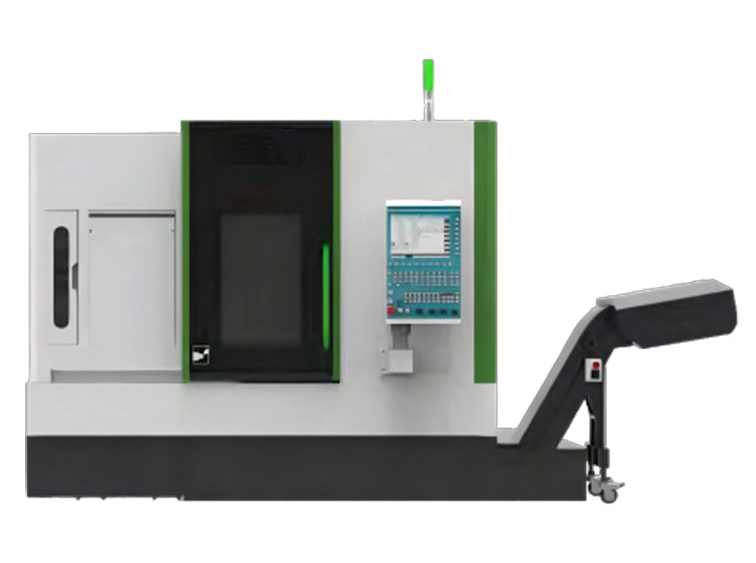

Features of Vertical CNC Lathes:

Compact machine structure, small footprint, and reasonable layout of functional components for convenient operation and maintenance.

Sleeve-type spindle structure ensures higher stability and reliability.

The machine tool bed is tilted at 45 degrees, offering the advantage of smooth chip removal.

It features a fully enclosed design for enhanced waterproofing and chip protection, and is ergonomically designed for easy operation.

Applications

The HTC16-5/6/8 series CNC horizontal gang tool lathes are used for turning small-sized parts in the automotive, hardware, and electronics industries.