Product Details

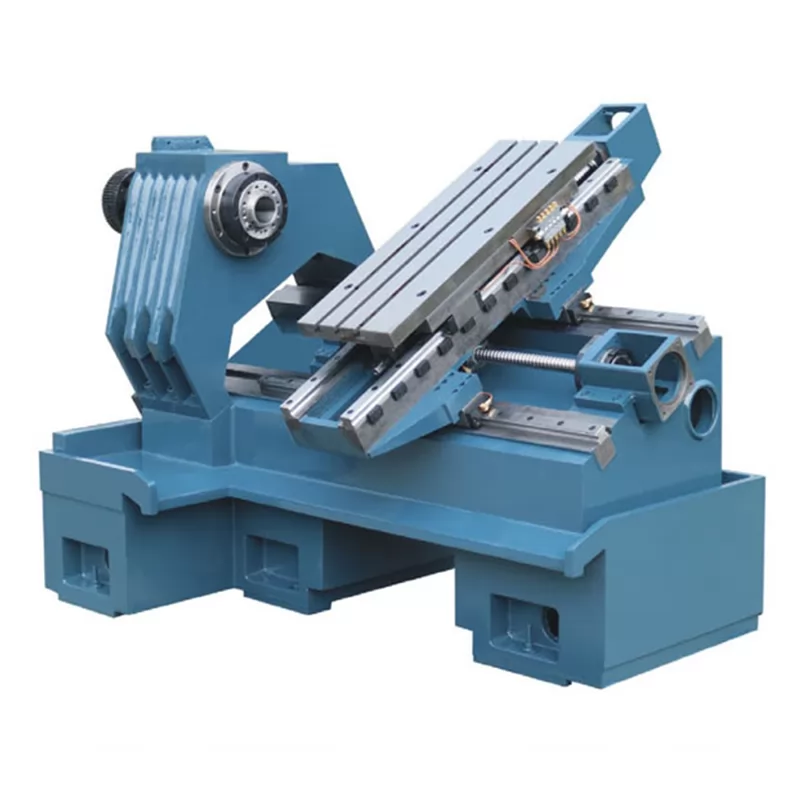

• The integrated base and bed casting has undergone a strict aging treatment, so high accuracy and rigidity is ensured.

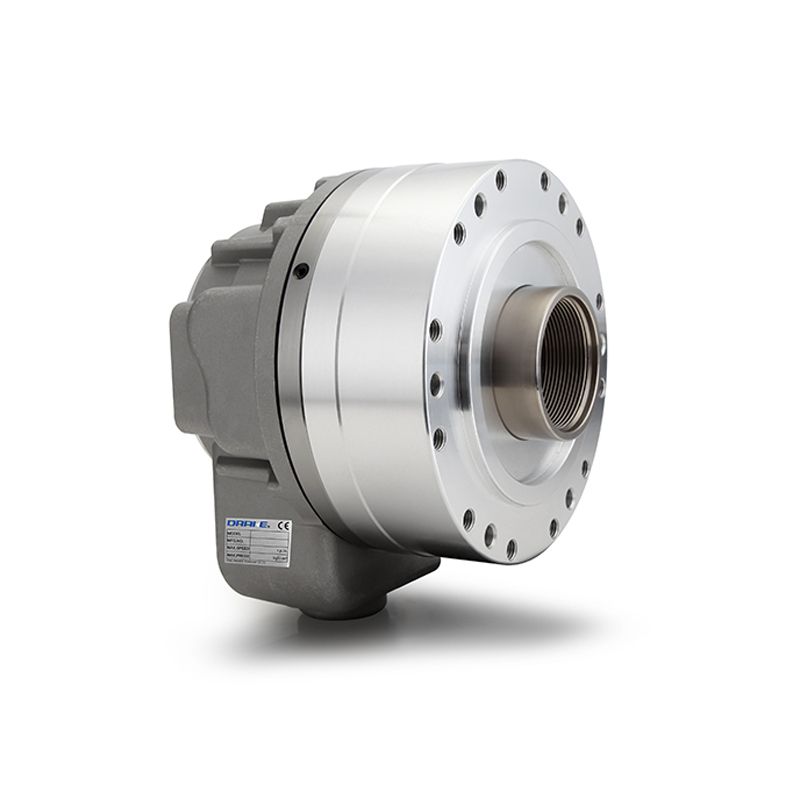

• High precision cartridge type spindle is equipped with a linear cylinder and col let chuck; the spindle rotates smoothly at high speed; turning roughness is up to Ra0.8~0.4.

• Precision hardened dovetail guideways or imported linear guideways improve the total rigidity of lathe so that the lathe has high precision and runs smoothly.

• Precision ball screw is located between guideways;side torque is eliminated, imported bearings especially for screw are used and smooth transmission is ensured.

• Feed screws in longitudinal and cross direction are directly connected with AC servo motors through zero clearance shaft couplings. High accuracy is ensured in transmission.

• The dovetail comb type tool block ensures easy setting, quick and precise tool change and less repeatability

• The high performance intermittent centralized lubrication system lubricates the machine bed guideways and X/Z-axis screws in time.

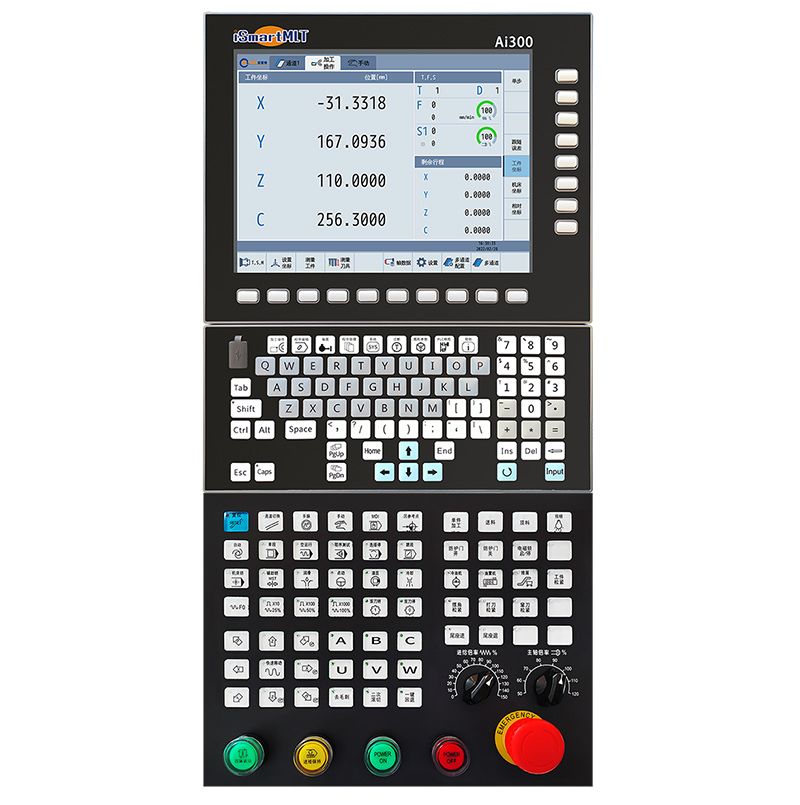

• The NC controller has color display and USB port, so data transfer is simple.

• The external electric cabinet is easy to service. The separate rear mounted coolant tank and chip box ensure fluent chip disposal and easy chip removal.

• The machine is jointly driven mechanically, electrically and pneumatically. Famous brand pneumatic and electric elements used on the lathe operate reliably.

• Full enclosed stainless steel guard ensures safe and friendly operation.

• The machine is suitable for efficient turning of large batch of small type work pieces in instrument,electronic connector and aerospace industries.

Product Size

None

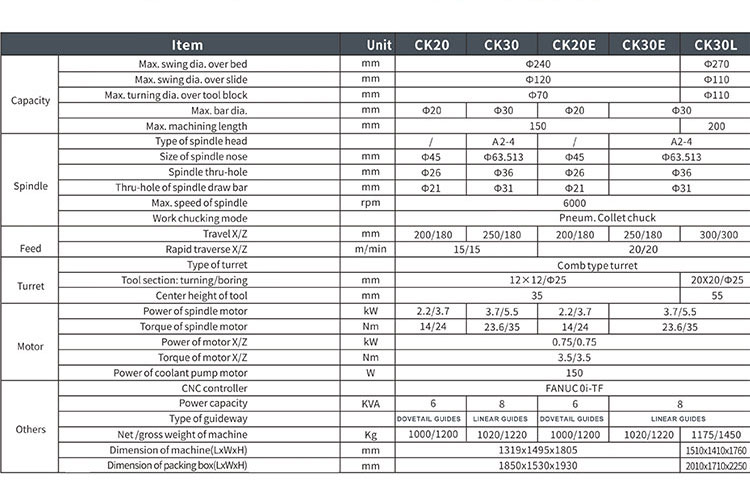

Product Parameters

STANDARD EQUIPMENT

Control system: FANUC Oi-TF

Spindle bearing: Imported high precision angular contact ball bearing Screw bearing: Im ported bearings especially for screw

Guideway: Hardened dovetail guideways or linear guideways Screw: Precision pretensioned ball screw

Collet chuck: Pneumatic draw down collet chuck

Turret: Precision dovetail comb type

Spindle motor: Servo main motor

Feed motor: FAN UC servo motor

OPTIONAL EQUIPMENT

• GSK/SYNTEC controller

• Spindle dish type brake

• Front/rear air blowing

• Drilling/milling unit

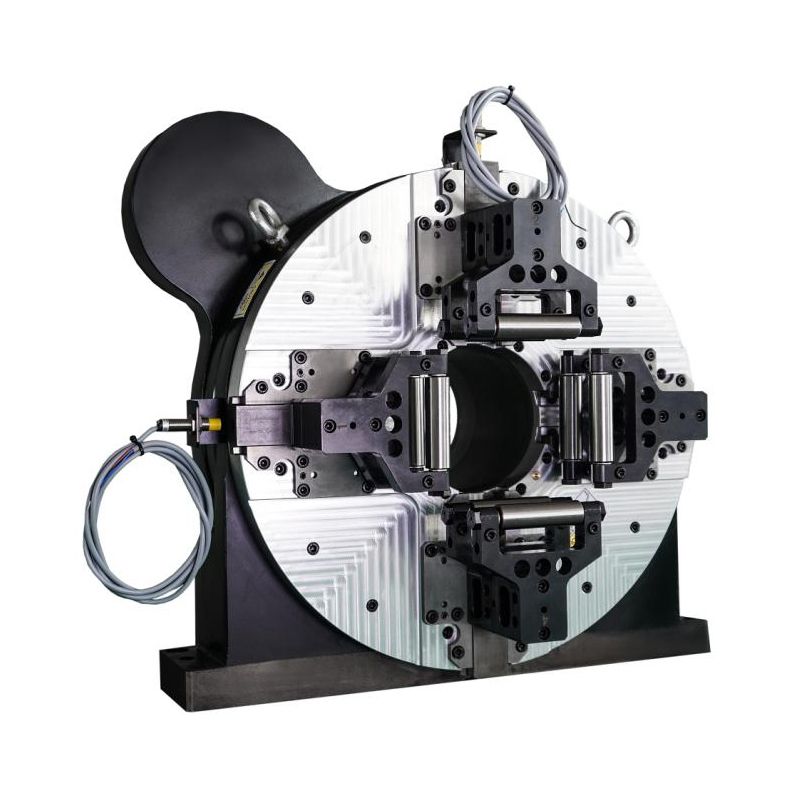

• 4" solid hydraulic 3-jaw chuck (CK20)

• 5" solid/hollow hydraulic chuck (CK30/30L)