Jul. 28, 2025

BT and SK toolholders differ significantly in several areas. These differences are explained in detail below.

BT Toolholder: BT is a Japanese standard, specifically MAS BT (a Japanese standard).

SK Toolholder: SK is a German standard, generally classified under DIN 69871 (a German standard).

However, some say SK toolholders are a high-speed version of BT toolholders.

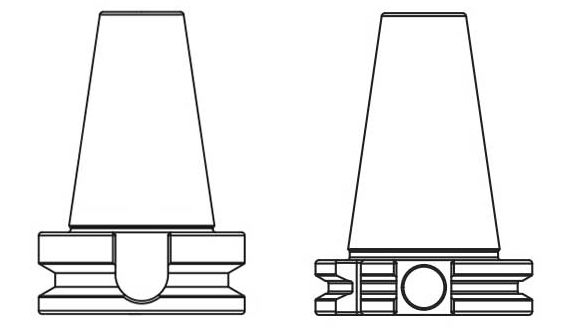

Flange and Keyway Design

Flange: The flange thickness of BT toolholders is relatively large, which enhances toolholder stability and rigidity at high rotational speeds. In contrast,

the flange thickness of SK toolholders is relatively thin, but still sufficient for most machining requirements.

Keyway: The two keyways in BT toolholders are of equal depth and are not milled through.

This design helps reduce vibration and noise during cutting and improves clamping stability.

On the other hand, the two keyways in SK toolholders are of different depths and are milled through, which provides a certain degree of installation flexibility.

Taper and Positioning Methods

Taper: Both BT and SK toolholders have a 7:24 taper, a structural commonality between the two. Therefore, when manually changing tools without a robotic arm,

BT and SK toolholders are generally interchangeable, as long as the corresponding lathe is changed.

Positioning Method: Although the taper shank is the same, the positioning methods of the two toolholders may differ.

BT toolholders rely primarily on the accuracy of the taper shank surface and the spindle interface for positioning,

while SK toolholders may utilize more complex positioning mechanisms to ensure higher machining accuracy and stability.

Applicable Scenarios and Performance

BT Toolholders: Due to their thicker flanges and locking mechanisms, BT toolholders generally provide higher clamping force and stability,

making them suitable for heavy-duty cutting and roughing. However, at higher spindle speeds (e.g., 40,000 RPM),

the tip of the BT toolholder may significantly deform due to centrifugal force, resulting in increased radial runout.

Therefore, they are generally not suitable for high-speed cutting.

SK Toolholders: SK toolholders offer high rigidity and precision, making them particularly suitable for high-speed, high-precision machining.

Their design emphasizes stability and practicality, ensuring that machining accuracy is maintained over time. The high-speed performance of the SK tool holder makes it ideal for high-speed cutting.