Aug. 30, 2024

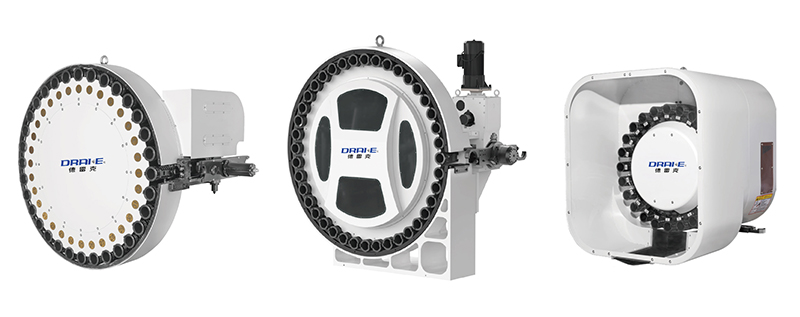

As we all know, the tool magazine structure of the machining center is very complex, especially the disc-shaped tool magazine.

In the normal operation of the machining center, the tool magazine often changes, so the machining center is prone to failure.

According to statistics, 50% of machine tool failures are related to the tool magazine.

Therefore, some issues must be paid attention to when using the machining center tool magazine.

Issues that should be paid attention to in the use of the CNC machining center tool magazine are to minimize the failure of the machining center tool magazine.

The following are precautions for using the machining center.

1. It is forbidden to load overweight and overlong tools into the tool magazine.

This prevents the tool from falling or colliding with the workpiece and fixture when changing the tool.

2. When loading the tool into the tool magazine, you must pay attention to the correct installation in the order in the tool magazine.

After loading, let the machining center idle and check whether the tool magazine is consistent with the required tool to prevent adverse consequences caused by incorrect replacement.

3. When the tool needs to be installed manually, we must ensure that it is installed in place,

fixed firmly, check whether the locking device on the tool holder is activated, and ensure these factors, otherwise unnecessary accidents will occur.

4. The operator of the machining center should check whether the tool magazine has returned to the correct position at any time,

simply return to zero, and then check whether the spindle of the machining center has returned to the tool change position.

If one of these two problems is found, it should be handled and fed back in time. Otherwise, the tool change cannot be completed, affecting the efficiency of the machining center.

5. In order to keep the tools, handles and sleeves clean, we must keep the tools, handles and sleeves clean.

6. When the machining center is started, the machining center should be idle to check whether the moving parts such as the tool holder and the manipulator are normal.

In particular, pay attention to whether important operating parts such as the travel switch and the solenoid valve are working properly.

The second is to check whether the hydraulic pressure of the manipulator is within the normal range and whether the tool is locked on the manipulator.

If the above problems are found, they should be fed back and handled in time.